Applicable Standards

UHPC150 ultra-high-performance concrete — GB/T 31387 Ultra-High-Performance Concrete

C100 Prestressed Duct Grout — GB/T 25182 Grouting admixture for prestressed structure

C150 High-Strength Grout — GB/T 50448 Technical code for application of cementitious grout

Key Features of the UHPC150 Series

Easy Construction: Self-consolidating workability with high slump-flow and low 1-h loss, enabling excellent pumpability and uniform consolidation for more consistent on-site quality.

Dual High Performance: Ultra-high compressive strength together with tensile strain-hardening toughness provides performance redundancy for critical load-bearing members.

Systematic Delivery: An integrated suite—prestressed duct grouting, structural grouting, and UHPC prefabrication(field-cast components—reduces multi-supplier coordination costs.

Customization: All products support custom development with matching technical services to optimize materials performance, construction efficiency, and environmental metrics.

UHPC150 Performance Parameters

Test Item | Standard Requirement | Test Result |

Workability | Initial slump-flow (mm) | 700±50 | 730 |

1 h slump-flow loss (mm) | ≤50 | 20 |

T500 time (s) | <10 | 6 |

Air content (%) | 1~4 | 2.5 |

Mechanical properties | 28-d specified strength value of (100×100×100) mm cubes (MPa) | ≥1.1 × characteristic compressive strength | 168.5 |

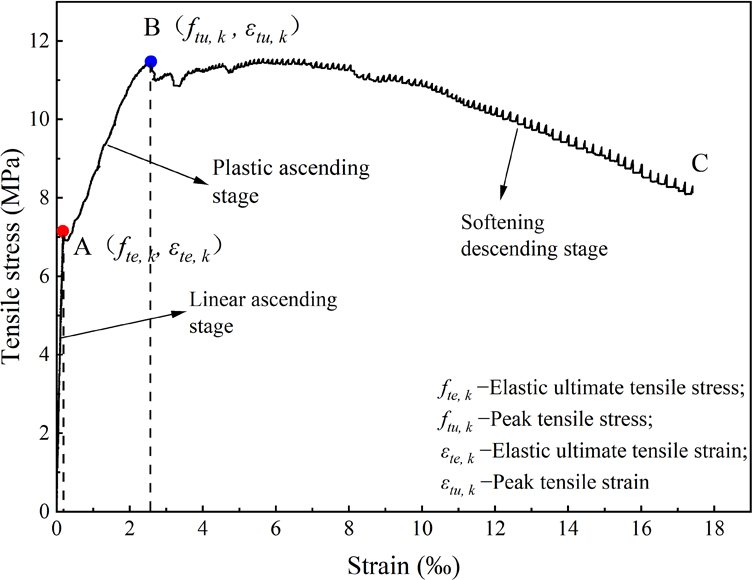

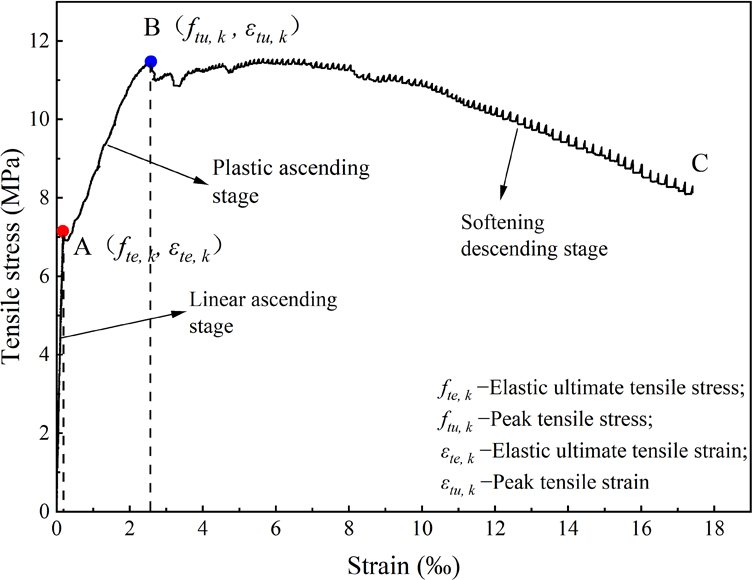

Characteristic elastic tensile strength fte, k (MPa) | ≥7.0 | 7.2 |

Characteristic ultimate tensile strength ftu, k (MPa) | ≥7.7 | 11.5 |

Ratio ftu, k / fte, k | ≥1.1 | 1.6 |

Tensile strain at ftu, k, εtu, k (%) | ≥0.15 | 0.265 |

Tensile behavior | Strain-hardening | Strain-hardening |

Elastic modulus (GPa) | ≥40.0 | 45.7 |

Applicable standard | GB/T 31387 Ultra-High-Performance Concrete |

Under direct tension, once after first cracking, steel fibers embedded in the dense cementitious matrix bridge the cracks and continue to transfer tensile stresses through fiber–matrix interfacial bond and shear, so the composite sustains high post-cracking tensile capacity and exhibits a metal-like tensile strain-hardening response. As shown in the figure below:

C100 Prestressed Duct Grout Performance Parameters

Test Item | Standard Requirement | Test Result |

Setting time (h) | Initial set | ≥4 | 9.42 |

Final set | ≤24 | 10 |

Grout consistency (s) | Initial | 18±4 | 21.2 |

30 min | ≤28 | 27.6 |

Bleeding at atmospheric pressure (%) | 3 h | ≤2 | 0.4 |

24 h | 0 | 0 |

Bleeding under pressure (%) | ≤3.5 | 1.8 |

Free expansion at 24 h (%) | 0~1 | 1 |

Restrained expansion at 7 d (%) | 0~0.1 | 0.014 |

Compressive strength (MPa) | 1d | / | 48.4 |

7d | ≥28 | 90.4 |

28d | ≥40 | 102.2 |

Flexural strength (MPa) | 1d | / | 6.2 |

7d | ≥6.0 | 12.7 |

28d | ≥8.0 | 17.9 |

Filling capacity | Pass | Pass |

Applicable standard | GB/T 25182 Grouting admixture for prestressed structure |

C150 High-Strength Grout Performance Parameters

Test Item | Standard Requirement | Test Result |

Maximum aggregate size (mm) | ≤4.75 | ≤4.75 |

Flow spread (mm) | Initial | ≥290 | 350 |

30min | ≥260 | 335 |

Vertical expansion (%) | 3h | 0.1~3.5 | 0.355 |

Difference (24 h-3 h) | 0.02~0.50 | 0.313 |

Compressive strength (MPa) | 1d | ≥20 | 64.8 |

3d | ≥40 | 99.5 |

28d | ≥60 | 155.8 |

Chloride content (%) | <0.1 | 0.06 |

Bleeding rate (%) | 0 | 0 |

Applicable standard | GB/T 50448 Technical code for application of cementitious grout |